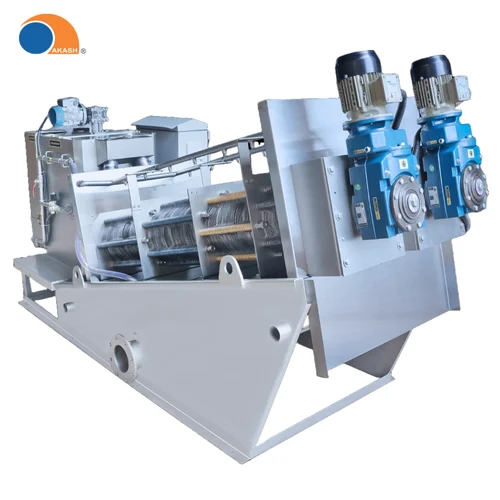

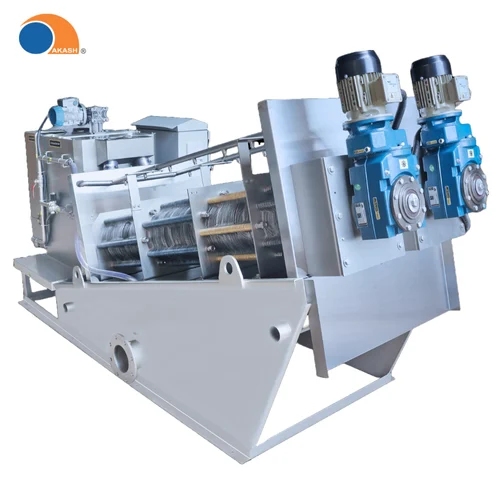

Screw Press Dewatering

AKASH Screw Press Dewatering Machines are advanced solid-liquid separation units engineered for efficient sludge management. The dewatering efficiency is precisely determined by three main factors: feed sludge concentration, screw speed, and system pressure in the compression zone.

Screw Press Dewatering

The AKASH Multi Disc Screw Press is a high-efficiency sludge dewatering machine designed for maximum reliability and sustainability. It separates solids and liquids effectively, reducing sludge volume while minimizing energy and water use. Ideal for ETP, STP, pulp & paper, and food processing industries, it lowers transportation and disposal costs and ensures regulatory compliance. Its robust construction, precision-engineered screw, and multi-disc mechanism provide continuous, low-maintenance operation with drier sludge and clearer effluent. Easy to install and integrate, it offers industries a cost-effective, sustainable solution for optimized wastewater management.

Product Details

Products Video

Details

| MODEL | INLET FLOW RATE (M³/HR @ 1% SLUDGE) | DRY SLUDGE (KG/HR) | ELECTRICAL POWER (KW) | DIMENSION (L×W×H) MM | RINSING WATER CONSUMPTION (L/H) | WEIGHT (KG) |

|---|---|---|---|---|---|---|

| ASDM -1080 | 1–5 | 0.93 | 1.5 | 3205 × 870 × 1115 | 24 | 700 |

| ASDM – 2210 | 6–10 | 1.47 | 6.0 | 1790 × 1160 × 1115 | 30 | 650 |

| ASDM – 1250 | 16–30 | 3.67 | 8.0 | 3430 × 830 × 1140 | 60 | 320 |

| ASDM – 1350 | 11–15 | 2.57 | 1.0 | 3205 × 1130 × 1785 | 60 | 520 |

| ASDM – 3350 | 61–80 | 0.36 | 3.0 | 4750 × 1495 × 1565 | 84 | 245 |

| ASDM – 1210 | 31–60 | 0.54 | 0.5 | 4370 × 1000 × 1085 | 18 | 225 |

| ASDM – 2350 | 61–120 | 0.30 | 12.0 | 4520 × 1095 × 1565 | 42 | 175 |

| ASDM – 2080 | 121–200 | 0.54 | 60.0 | 2125 × 1065 × 2310 | 42 | 1220 |

| ASDM – 1115 | 401–600 | 0.55 | 20.0 | 2125 × 1255 × 2310 | 120 | 4000 |

| ASDM – 2115 | 201–400 | 0.92 | 40.0 | 1985 × 2045 × 2310 | 180 | 2215 |

Features

High Dewatering Efficiency: Achieves up to 15–20% dry solids content in the cake.

Continuous Operation: Designed for 24/7 operation with minimal downtime.

Low Energy Consumption: Optimized screw design reduces power requirements.

Self-Cleaning Mechanism: Integrated wash water system ensures clog-free operation.

Compact Design: Space-saving footprint suitable for various installations.

Automated Operation: PLC control with HMI for user-friendly interface.

Wide Application Range: Handles municipal, industrial, and food processing sludges.

Durable Construction: Stainless steel components for longevity and corrosion resistance.

Minimal Maintenance: Reduced wear parts and easy access for servicing.

Environmentally Friendly: Low noise and vibration levels during operation.

SCOPE OF SUPPLY (Screw Press Dewatering)

A. Dewatering Unit

Design: Modular screw press system with integrated thickening, filtration, and compression zones.

Materials: Constructed from stainless steel (304/316) for durability and corrosion resistance.

Components: Includes screw shaft, fixed and moving rings, and wedge wire screen.

B. Auxiliary Systems

Flocculation System: Polymer dosing unit with mixing tank for sludge conditioning.

Control Panel: PLC-based automation with HMI for real-time monitoring and operation.

Wash Water System: Integrated wash water pump and flushing system for self-cleaning.

C. Piping & Valves

Inlet/Outlet Connections: Flanged connections for sludge feed and filtrate discharge.

Non-Return Valve: Prevents backflow and ensures unidirectional flow.

Flexible Connectors: To accommodate vibrations and misalignments.

D. Documentation & Support

Technical Drawings: General Arrangement (GA) and dimensional drawings.

Operation Manual: Detailed guidelines for installation, operation, and maintenance.

Warranty: Standard warranty period with after-sales support.

Applications of Screw Press Dewatering

AKASH Screw Press Dewatering Machines are advanced solid-liquid separation units engineered for efficient sludge management. The dewatering efficiency is precisely determined by three main factors: feed sludge concentration, screw speed, and system pressure in the compression zone.

- Water & Wastewater Treatment Plants:

Sludge thickening and dewatering in STPs, ETPs, and municipal sewage treatment facilities - Food & Beverage Industry:

Efficient separation of organic waste, fruit pulp, and processing residues - Pulp & Paper Industry:

Dewatering of paper sludge, fiber recovery, and wastewater treatment applications - Pharmaceutical & Chemical Industry:

Separation of process waste, chemical slurries, and biological sludge - Textile Industry:

Handling and dewatering of dyeing, printing, and finishing wastewater sludge - Agriculture & Livestock Farms:

Manure management, compost preparation, and biogas plant feed processing - Aquaculture:

Treatment and dewatering of aquaculture waste, pond sludge, and fish farm residues - Mining & Mineral Processing:

Dewatering of mineral slurries, tailings, and fine particulate waste - Leather & Tanneries:

Separation of water from tannery sludge and chrome-containing residues - Power Plants & Industrial Utilities:

Sludge handling in ash slurry and flue gas desulfurization (FGD) systems

Years Industry Experience

Clients across India

Reapt Client Rate

Cities in PAN India

Blowers Installed

Get in touch

How can we help your business?

Quickly maximize timely deliverables for real-time schemas. Dramatically maintain clicks-and-mortar solutions without functional solutions.

We are here to help you.

FAQs

A Multi Disc Screw Press is a type of screw press dewatering machine used to separate water from sludge or slurry. It uses a combination of screw rotation and multi-disc filtration to deliver continuous and energy-efficient dewatering.

Industries such as wastewater treatment (ETP/STP), pulp and paper, food & beverage, textile, dairy, chemical processing, and oil refining use Multi Disc Screw Presses for efficient sludge handling.

Thanks to its self-cleaning design and low-wear components, our Multi Disc Screw Press requires minimal maintenance, reducing operational downtime.

Our models vary in energy consumption from as low as 0.5 KW to 60 KW depending on the sludge load and flow rate. The system is highly energy-efficient compared to traditional technologies.

Absolutely! We offer tailored solutions based on your input volume, sludge type, and space availability. Contact us for a detailed consultation.