What is a Multi-Disc Screw Press and How Does It Work?

What’s a Multi-Disc Screw Press ?

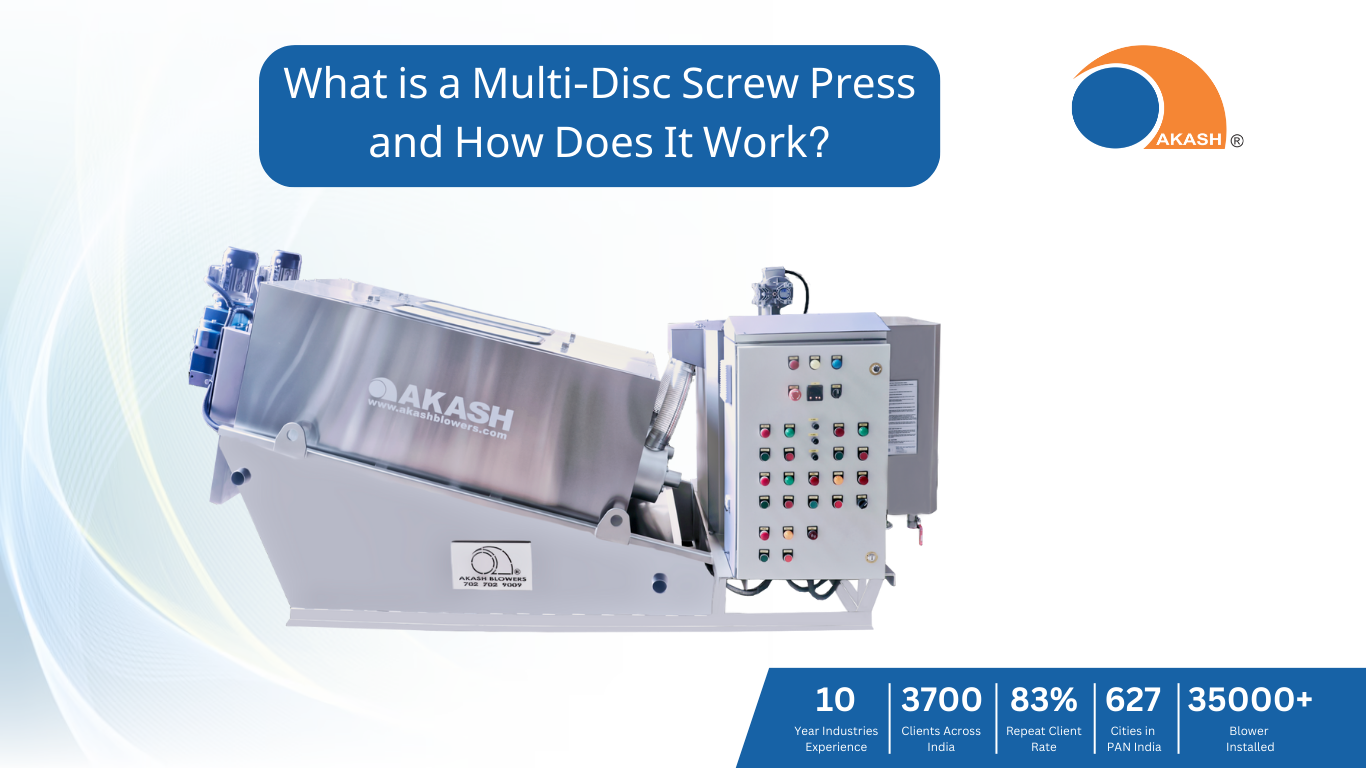

If you work in a factory or a wastewater treatment plant, you’ve probably heard of sludge dewatering. And if you want an efficient, hassle-free machine, the Multi-Disc Screw Press (MDSP) is the way to go. It’s a solid sludge dewatering machine that separates water from sludge without high energy consumption or frequent maintenance.

Forget the old-school belt filter presses and centrifuges—this machine is low-power, clog-free, and runs on auto mode.

How Does a Multi-Disc Screw Press Work?

Here’s how this beast operates in 5 simple steps:

1. Sludge In, Chemical Added

First, the sludge goes into a flocculation tank, where a polymer or coagulant is added. This chemical helps the small sludge particles stick together, forming bigger flocs. This makes water separation much easier.

2. Thickening Process Begins

Once inside the screw chamber, the discs allow free water to escape through tiny gaps, thickening the sludge before moving forward.

3. Dewatering Action

A rotating screw slowly pushes the sludge forward. As it moves, the gaps between the discs get smaller, applying pressure to squeeze out more water.

4. Water Separation

The separated water, called filtrate, drains out through the gaps and is collected for further treatment.

5. Sludge Cake Discharged

The leftover, highly compressed sludge—known as sludge cake—is discharged. This dry sludge can either be disposed of or repurposed for other uses like biofuel production.

Why Choose a Multi-Disc Screw Press?

Wondering why this machine is a game-changer? Here’s why:

✅ Saves Energy – Runs on low power, reducing electricity costs.

✅ Compact Design – Takes up less space compared to traditional machines.

✅ Low Maintenance – Fewer moving parts mean less wear and tear.

✅ Fully Automatic – Once set up, it runs on its own without constant supervision.

✅ No Clogging Issues – Self-cleaning system keeps it running smoothly.

✅ Eco-Friendly – Low noise and vibration, making it a cleaner, greener option.

Also Check Our Multi Disc Screw Press product Page

Where is It Used?

This machine fits in almost any industry:

🔹 Wastewater Treatment Plants (WWTPs) – Handles municipal and industrial sludge.

🔹 Food Processing Units – Manages organic sludge from food waste.

🔹 Pharmaceutical & Chemical Plants – Treats chemical sludge effectively.

🔹 Paper & Pulp Industry – Helps remove excess moisture from fiber waste.

🔹 Dairy & Beverage Industry – Processes sludge from milk and beer plants.

Conclusion

If sludge management is a headache for your business, a Multi-Disc Screw Press is the perfect solution. It’s energy-efficient, low-maintenance, and delivers top-notch performance. And if you want the best-quality Multi-Disc Screw Press, get in touch with Akash Blowers Private Limited—they’ll sort you out! 😎

🚀 Stay Updated with the Latest in Sludge Dewatering & Industrial Solutions! 🚀

Join our WhatsApp Channel now for exclusive insights, expert tips, and industry updates. 📲👇

Don’t miss out—stay ahead with Akash Blowers! 🔥💡