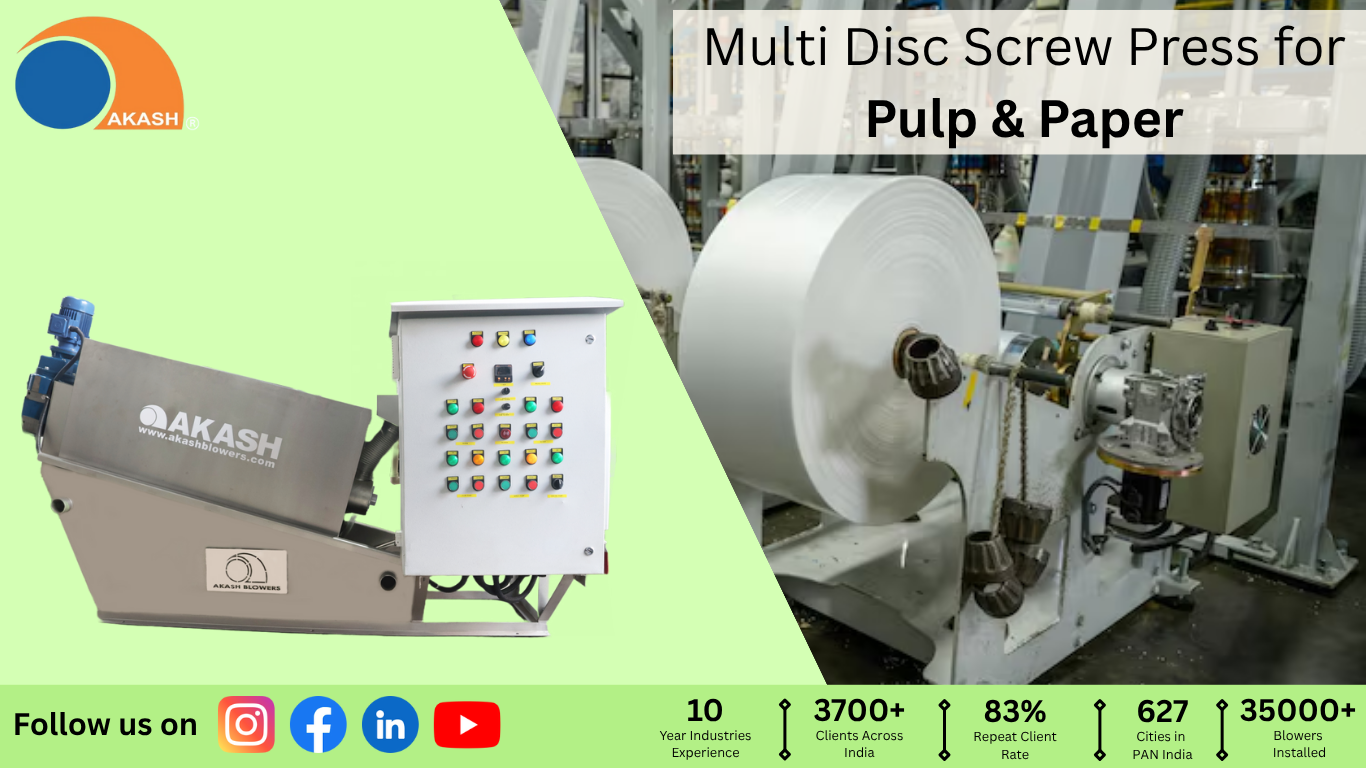

Multi Disc Screw Press for Pulp & Paper: Revolutionizing Sludge Dewatering | Akash Blowers

Combat high costs & inefficient dewatering in pulp & paper. Discover how Akash Blowers’ Multi Disc Screw Press tackles pulp sludge, black liquor, and de-inking sludge for superior dryness & savings. Call 7419753355.

The pulp and paper industry, a very important element of the human way of life today, is faced with challenges in the management of its operational by-products peculiar to itself and very significant. From the raw stages of pulp production to the final finishing of paper, slurries and sludges of various forms are ceaselessly generated as an unavoidable reality. They include Pulp Slurry, Black Liquor, De-inking Sludge, Paper Mill Effluent Sludge, and Fiber Recovery Slurry-these make a formidable pain-points set for a plant manager and environmental compliance.

At Akash Blowers Private Ltd., we know these problems quite well. We have first-hand witnessed how slow and inefficient dewatering processes cripple profitability, inflate operating costs, and even lead to environmental noncompliance for years as first-hand witnesses of such cases. Things are changing, however, for the better. The new Multi-Disc Screw Press technology now stands to become a new figure of strength and high performance for acute needs of dewatering in the pulp and paper industry.

Attention Readers Join Our WhatsApp Community to get latest updates in blower Industry Click Here

Pain Point: The Inefficiency of Traditional Dewaterings Against Pulp and Paper Sludges

Let’s delve into the specific struggles that conventional dewatering methods often fail to address in this demanding sector:

- High Moisture Content and Volume: Pulp and paper sludges are notoriously high in water content. This translates to massive volumes of waste that require extensive storage, transportation, and disposal, leading to significant logistical and financial burdens.

- Sludge Character Variability: Depending on the type of paper produced, pulping process used, and content recycled, sludges can vary wildly in composition. This has frequently resulted in inefficient dewatering as well as constant operational adjustments and less than ideal performance of conventional dewatering devices.

- Environmental Legislation Compliance Pressure: Very tough rules dictate water quality requirements for the discharged effluents and solid waste disposal. Noncompliance with these rules will cost fines, damage reputation, and in some cases shutdowns. Therefore, the level of dryness to optimize in dewatered sludge is significant for compliance and lower costs in landfill.

- High Operating Costs: The traditional technologies employed for dewatering, mainly belt presses or centrifuges, go hand in hand with high energy consumption, a certain use of chemically prepared additives, and an intensive labor for operation and maintenance. In fact, the costs brought about by filter cloths, continuity in washing, and frequent repairs quickly take their toll on profits.

- Odor- and hygienie- Bad Conditions: In storing wet sludge in large volumes, it usually creates a stink, attracts pests, and makes an unhygienic working condition. This lowers the morale among employees and moreover can be a nuisance for people living around the area.

- Loss of Fiber with Less Recovery: In a fiber recovery process, fibers being washed with wastewater go on to create a direct financial loss and lower source effectiveness because of inefficient dewatering.

The Solution: Unleashing the Power of the Multi-Disc Screw Press for Pulp & Paper

Using the Multi-Disc Screw Press, a dewatering technology is going to be discussed that has the power to handle some of these very challenges. With Akash Blowers Private Limited, it sets factory standards of performance and economy along with greater efficiency for the pulp and paper industry.

Ultimate technology with the following:

- Multi-Disc Screw Press with superior dewatering efficiencies for high dryness levels: Our Multi-Disc Screw Press dewaters sludge to very high dryness levels. The configuration has a central screw with several fixed and moving rings, resulting in a continuously low-speed dewatering action. This very effectively separates solids from fluids, thus lowering the volume of filter cake to a level where transportation and disposal are cheaper. Among the many presses we manufacture, we have established results for Pulp Sludge Dewatering Presses, De-inking Sludge Dewatering Presses, and Paper Mill Effluent Sludge Presses.

- Multi-Disc Screw Press Robustly Handles Variable Sludge Consistencies: The very robust design of the Multi-Disc Screw Press allows sludges of varying solids concentrations and characteristics to be handled-imprecision very common in the pulp and paper industry. The self-cleaning nature of the press averts clogging, thus letting it work without fail and uninterrupted over years with varying fibrous or sticky sludges like Fiber Recovery Slurry.

- Energy Saving with the Highest Savings: Energy efficiency is characteristic of our Multi-Disc Screw Press. Running at low speeds with least moving parts, these presses consume very little energy as compared to centrifuges and belt presses. And, lower energy consumption will mean lower expenses when it comes to paying for electricity and smaller carbon footprints, all in line with current sustainability goals.

- Chemical Savings with Multi-Disc Screw Press Technology: The efficient mechanical dewatering action of the Multi-Disc Screw Press often requires less polymer addition-or even no polymer addition-at all, compared to other technologies. This reduces chemical costs drastically, thereby strengthening the commercially viable aspect of sludge management.

- Our automated, low-maintenance Multi-Disc Screw Press: The Multi-Disc Screw Presses are designed for continuous, automated operation with very little supervision. The unique self-cleaning mechanism, created as an effect of relative motion of fixed and moving rings, prevents clogging and obviates the need for thorough cleaning. This hugely reduces maintenance and labors costs, making it suitable for continuous processes as a Pulp Sludge Dewatering Press.

- Low-Maintenance Operation with Flash Investment of Multi-Disc Screw Presses: A strong compact design of the Multi-Disc Screw Press allows it to be installed in tight spaces, offering flexibility for any plant layout or future expansion.

Effective Fiber Recovery with a Dedicated Fiber Recovery Screw Press: Gentle yet effective dewatering processes with a Fiber Recovery Screw Press minimizes fiber degradation and loss while maximizing recovery of these valuable materials back into the production stream.

Akash Blowers Private Limited: Your Partner in Efficient Multi-Disc Screw Press Dewatering

At Akash Blowers Private Limited, commitment to state-of-the-art dewatering solutions for the pulp and paper industry is paramount. Our Multi-Disc Screw Presses are engineered with precision to employ quality materials that ensure durability, reliability, and long-term performance under conditions prevalent in the harshest sectors of industry.

We offer tailored solutions because we understand that each pulp and paper mill need different things. Whether it is a de-inking sludge dewatering press or an alternate company paper mill effluent sludge unit, we collaborate with our clients to design and implement the right system. Click here to visit our multi disc screw press product page and get quotation.

Frequently Asked Questions (FAQs) About Multi-Disc Screw Presses

- What types of sludges can a Multi-Disc Screw Press handle in the pulp and paper industry?

The Multi-Disc Screw Press is fairly versatile and can efficiently dewater a range of sludges from the pulp and paper industry, i.e., Pulp Slurry, Black Liquor, De-inking Sludge, Paper Mill Effluent Sludge, and Fiber Recovery Slurry. Its robust design allows it to handle sludges with differing consistencies. - How does a Multi-Disc Screw Press reduce operational costs?

Our Multi-Disc Screw Press cuts a great deal in operational costs through its low electricity consumption due to slow-speed operation, the very minimal-to-no dosing of chemicals required, and low labor requirement since it is self-cleaning and automated. Higher dryness means lower disposal cost as well. - Is the Multi-Disc Screw Press easy to maintain?

Yes, low maintenance counts as one of the prime advantages of the Multi-Disc Screw Press. Clogging is prevented by the unique self-cleaning mechanism with the movement of fixed and moving rings, whereby the press does not require constant washing like other dewatering equipment. - What is the footprint of the Multi-Disc Screw Press compared to other dewatering technologies?

The Multi-Disc Screw Press boasts a remarkably compact footprint compared to conventional dewatering equipment like belt presses or centrifuges. This makes it an ideal solution for facilities with limited space, offering greater flexibility in installation. - Can a Multi-Disc Screw Press help with fiber recovery?

Absolutely. For applications like Fiber Recovery Screw Press, the gentle yet effective dewatering process minimizes fiber damage and loss, ensuring that valuable fibers can be efficiently recovered and reintroduced into your production process, enhancing resource utilization.

Also Read:

How twin lobe blowers increase efficiency in wastewater treatment plants

How to choose the right capacity multi disc screw press (MDSP) machine for your plant?

Are escalating sludge disposal costs and operational headaches holding your pulp and paper mill back? It’s time to experience the difference a high-performance Multi-Disc Screw Press can make.

Unlock significant savings, boost efficiency, and ensure environmental peace of mind.